Introduction

Large disc pelletizing machine is one of the scientific and technological products developed by Changsha Tianwei. The product has the advantages of stable operation, high pelletizing quality, low energy consumption and simple maintenance. In the same industry in the country in a leading position.

In the process of R & D, our company's technicians have made use of the advanced nature of the similar products in Germany, and integrated the working conditions at home and abroad, avoiding the instability and easily vibrating characteristics of the cantilever shaft supporting structure of the traditional ball maker. Through the actual production inspection of dozens of projects at home and abroad, it has been highly praised and highly recognized by users.

working principle

Disc pelletizing machine is a kind of disc-shaped pelletizing equipment, which can make fine-grained powder into spherical particles and meet the requirements of the next process.The pelletizing material rolls and rubs under the action of gravity, centrifugal force and friction force in an inclined and rotating disc, and forms a mother ball with proper water supplement.When the fine material rolls on the wet surface of the cue ball, the cue ball grows up and has certain strength. The pellets with different particle sizes automatically run along different tracks in the disc, and the finished pellets that meet the requirements are discharged from the disc.

Product advantages and innovation

Product advantages and innovation

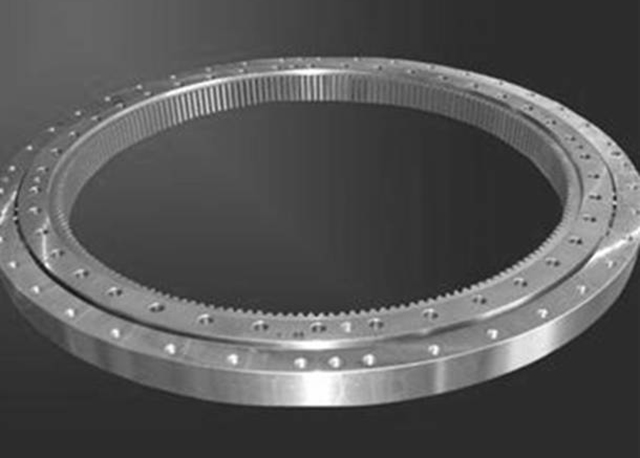

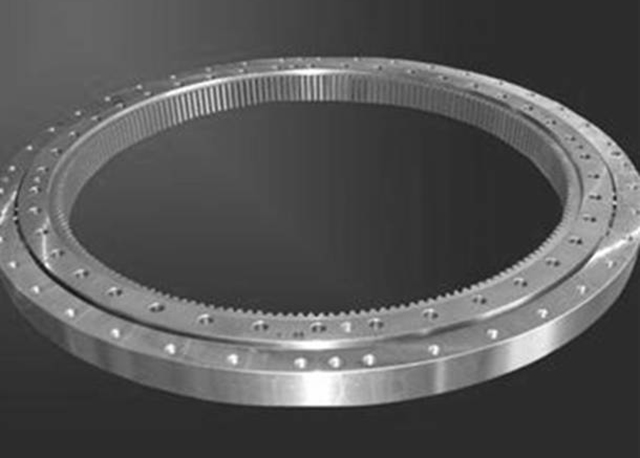

* Large diameter slewing bearing is adopted, and the disc body of pelletizing plate is plane support. During pelletizing, the fuselage is stable without vibration, and the pelletizing quality is high.

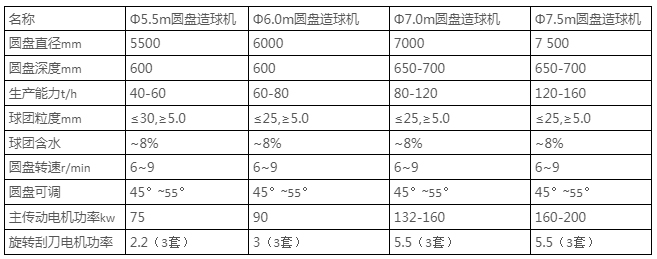

* The output of 6-meter pelletizer is 60-90 tons per hour, and that of 7.5 meters is 120-160 tons per hour.

* The energy consumption per ton ball is 0.7-0.8 of the traditional pelletizer, which brings considerable economic and social benefits to the enterprise.

* The maintenance is simple, and there is no need for routine maintenance during the use of the equipment. The 7.5m pelletizing machine is about 4.3t of overhaul parts. Compared with the traditional pelletizing machine, it is more simple and practical, with less fault and maintenance.

* The fully closed internal meshing gear transmission system is adopted to isolate the transmission gear from the external dust, which makes the tooth surface wear free from dust and pollution, reduces the failure rate, prolongs the service life of the gear and ensures the operating rate.

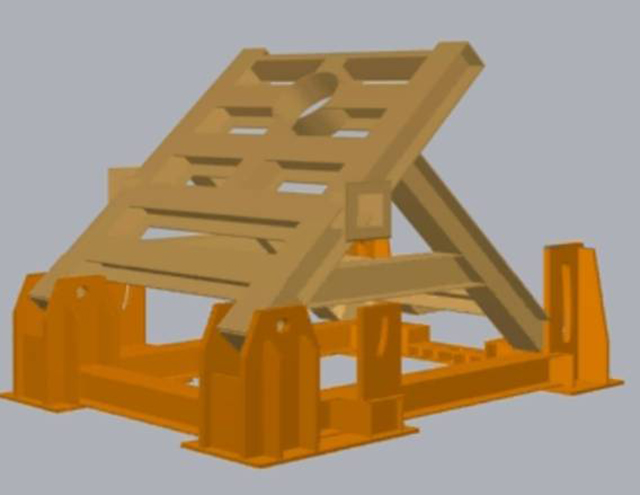

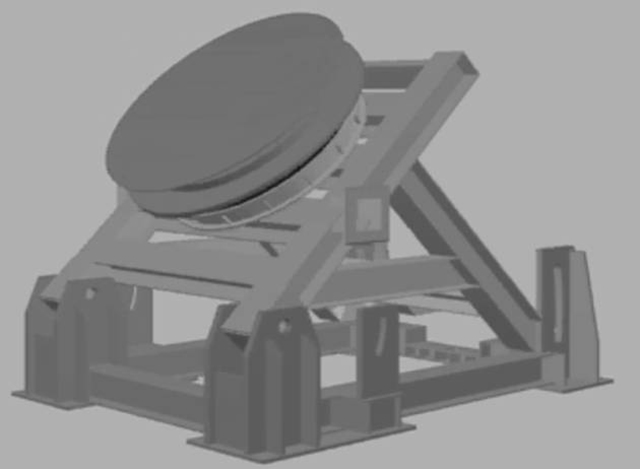

* The disc body of the pelletizing plate is a plane support, running smoothly and without vibration.

* The center distance and clearance of big and small gears are guaranteed by machining, and the transmission precision is high. The clearance of traditional pelletizing in China should be adjusted manually. If the clearance is too large, too small, or too biased, it will affect the transmission precision and service life. Some balls need to be adjusted once every two months.

Diagram of slewing bearing

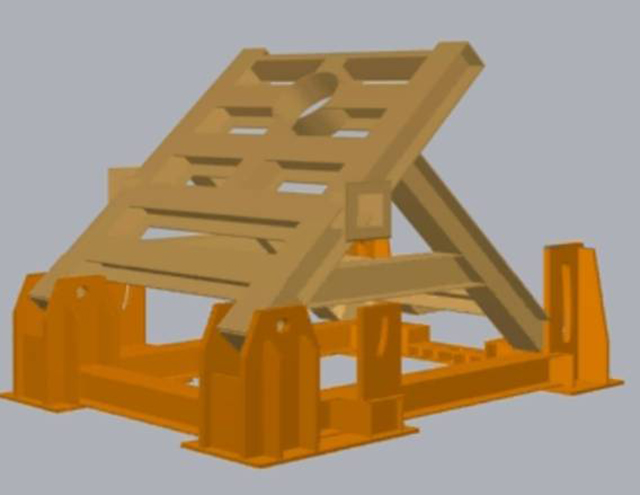

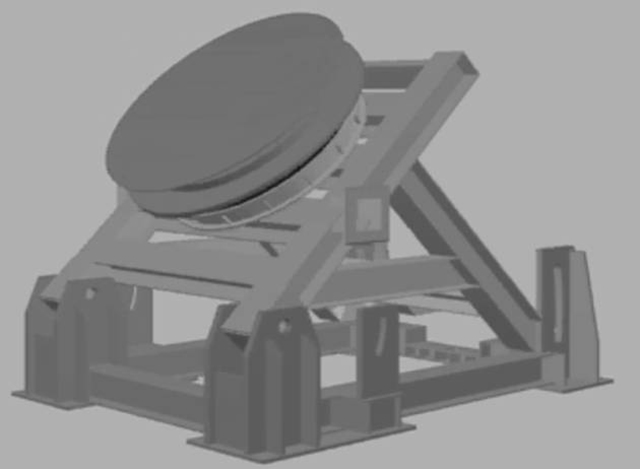

Plane supporting structure of pelletizing plate

Plane supporting structure of pelletizing plate

The plane support main frame formed by pelletizing plate

The plane support main frame formed by pelletizing plate

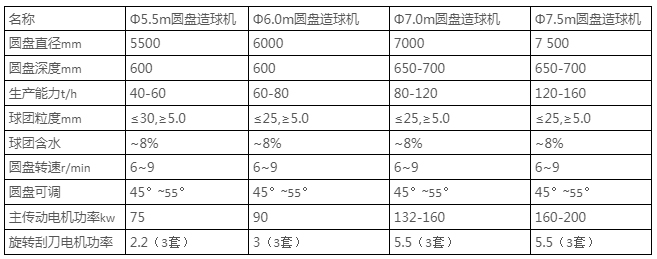

technical parameter

technical parameter

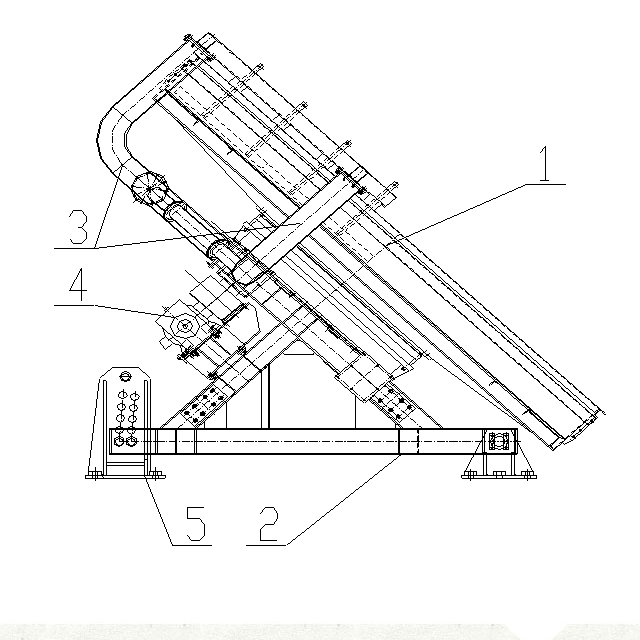

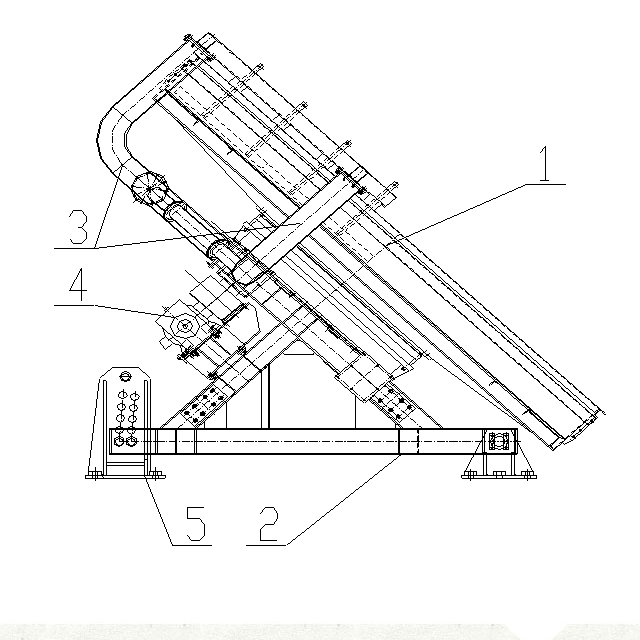

Figure of pelletizing machine

Figure of pelletizing machine

attention

attention  Mobile website

Mobile website